Our geography uniquely impacts our building materials

22 Feb 2022

We’re all aware that we have high levels of UV and that these can quickly burn our skin if we forget to apply sunblock. But it’s also been proven that the durability, performance and deterioration rate of the products we construct with are influenced by climatic conditions and sun exposure.

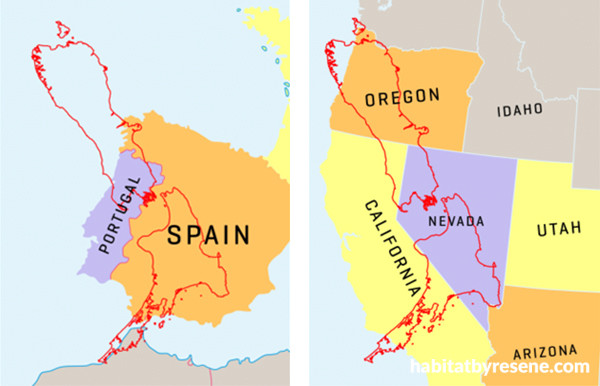

Our absolute UV levels and UV index numbers are a bit surprising, on the face of it, given that similar latitudes on other continents are typically about 20% lower than the UV levels we have here. For the sake of comparison, the alignment of New Zealand’s latitude has been mocked up with the inverse latitudes of Southern Europe (left) and North America (right) below.

There are several possible reasons our UV exposure is higher. While urban myths about the ozone hole and sunshine hours may jump to mind, our clean air as well as the Earth’s orbit and axis tilt, which brings us closer to the Sun during our summer months, are key factors. The National Institute of Water and Atmospheric Research (NIWA) has confirmed that, in the summertime, the UV is higher in New Zealand than at comparative northern hemisphere latitudes.

Its climatic differences like these that remind us how lucky we are to have independent research organisations like BRANZ who use an impartial evidence-based approach to improve the performance of the New Zealand’s building systems. Past research by their team confirmed effects on plastic building products by sunlight, which Nick Marston highlighted in Build Magazine along with fascinating findings on climatic variations.

The technical team at Resene has been researching and testing the effect the sun in New Zealand has on both coatings and the substrates beneath them for many decades. While their findings confirm that our harsh UV levels do indeed affect how long colour lasts, the integrity of the coatings themselves and the deterioration of the materials they’ve been applied to, there has been much work done to combat these effects – and to great success.

Since every material comes with different properties, uses and demands, each requires different coatings to keep it looking and functioning at its best. The fruits of the Resene Technical team’s labour have yielded higher performance and a greater number of decorative and protective Resene coatings to choose from than ever before. As a homegrown brand, the company’s research has focused on moved forward the development of formulas that have been specialised for our specific climate, including innovative products like Resene CoolColour heat reflective technology and Resene Clearcoat UVS.

“Whether it be a paint, wood stain or clear finish, when we use a coating on a building material, we’re unapologetically trying to stop the forces of nature; to slow down or, ultimately, halt its biodegradation. We want to keep that beauty in stasis so that it can be enjoyed for the life of the structure," says Resene Technical Director Colin Gooch, who has spent more than five decades focused on developing products that attempt to do just that. “The best thing we could hope to do is to make a coating so good that it completely protects the substrate.”

Dark colours are a popular look for exteriors, but it’s important to be careful with how and where you use them, especially on northern, western and eastern elevations. While it can be done, it’s important to be aware that these surfaces are going to be exposed to more UV and thus will require more frequent maintenance. When you do choose darker colours, it’s recommended you specify a Resene CoolColour formula, as its special technology will reflect more of the sun’s rays than a standard version of the colour and help protect your substrate from absorbing too much heat.

Resene Clearcoat UVS is the recommended clear topcoat to use outdoors over brightly painted details to filter out UV light and help keep the colour long lasting. It’s ideally used on areas that are hard to reach. Colin says that it’s a good choice for applying over low gloss finishes and generally recommends its use over Resene Lumbersider. “Two coats are ideal as it can be easy to miss a spot as you’re applying it; but if you start with a lower gloss basecoat such as Resene Lumbersider, it’s easier to see due to the contrast in sheen levels. Resene Clearcoat UVS is glossy, so it looks especially great when used over bright colours – which can also be more sensitive to UV light.”

This finial in Resene Dynamite was topcoated with Resene Clearcoat UVS to maintain the integrity of the colour coat and substrate.

To find out more about how best to protect your project against the effects of hard UV light, get in touch with your local Resene representative for technical guidance (book a free catch up at www.resene.com/repvisit), ask a Resene Paint Expert for help with your coating selections, catch up on past architects memos and our technical stories in past issues of BlackWhite magazine.

Special thanks to Nick Marston and the BRANZ team for sharing words and research to support this story.

Published: 22 Feb 2022